Inorganic liquid waste treatment at Center for Environmental Science

Our college began on-campus disposal of inorganic liquid waste in 1980.

In 2002, the treatment facility was upgraded and the treatment method was changed from the neutralizing coagulation method to the iron powder method.

This facility has treated more than 20,000 liters of flue gas flushing wastewater from organic liquid waste treatment facility on campus, in addition to inorganic liquid waste discharged from laboratories.

The iron powder method is a method for recovering heavy metals from liquid waste by precipitating heavy metals with iron powder having reducing ability and coagulating them with dissolved iron ions.

2002-2022

After more than 40 years of on-campus treatment of inorganic liquid waste, in 2017 we shut down organic liquid waste treatment facility and began outsourcing disposal of organic liquid waste, resulting in a significant decrease in the amount of inorganic liquid waste treated.

Additionally, due to the aging of the inorganic liquid waste treatment facility, in 2022 we terminated our on-campus inorganic liquid waste treatment.

From 2023, the collection, transportation, and disposal of inorganic liquid waste will be outsourced to licensed contractors.

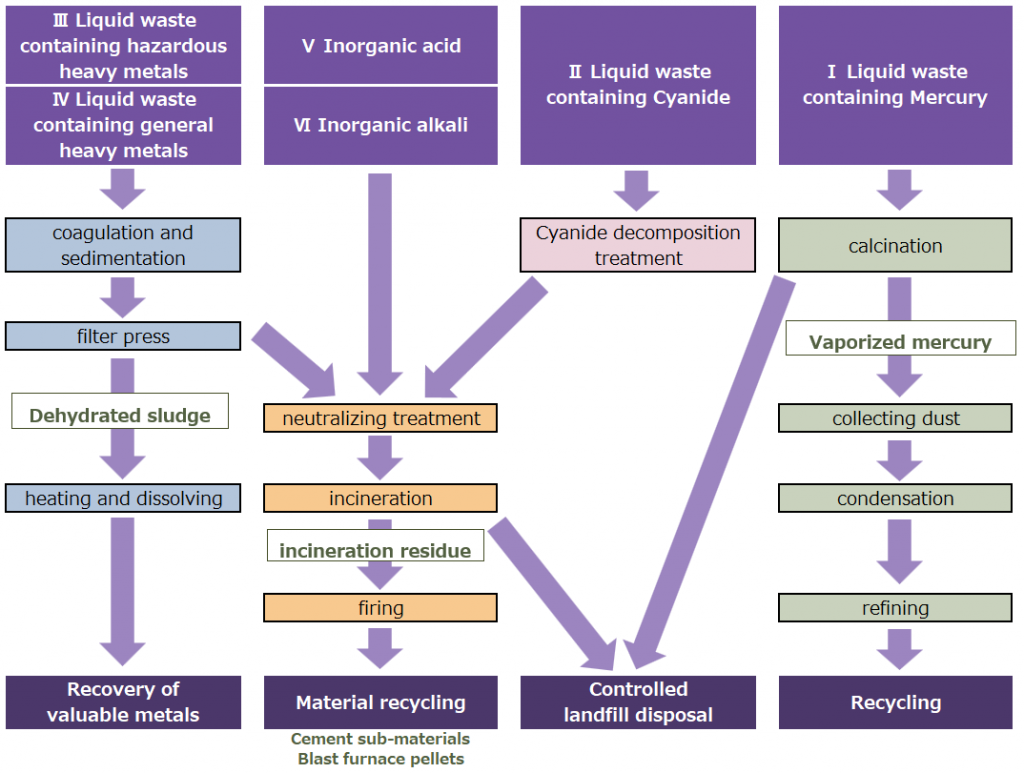

Flow of inorganic liquid waste treatment

Separation and storage of inorganic liquid waste

▼

In each laboratory, inorganic liquid waste should be stored in following six categories according to the substances it contains.

| containing substances | |

|---|---|

| Ⅰ. | organic and/or inorganic mercury compounds |

| Ⅱ. | cyanide compounds |

| Ⅲ. | hazardous heavy metal compounds; Cr, Pb, Se, Cd, As |

| Ⅳ. | general heavy metal compounds |

| Ⅴ. | inorganic acids |

| Ⅵ. | inorganic alkalis |

Storage precautions

- If there is a relatively large amount of liquid waste that has the same history of generation, it is desirable to store it separately and not mix it with other liquid waste, even if it is in the same category.

- When depositing liquid waste into storage containers, accurately record and label the contents.

- Note that only designated polyethylene containers of 20L may be used for outsourced disposal inorganic liquid waste. Never use damaged containers.

More detailed precautions on storage

▼

Inorganic liquid waste should be separated and stored safely, observing the following precautions.

More detailed precautions for each liquid waste category

| Category by contained substances | Target Substances | Points of Attention |

|---|---|---|

| I. Mercury compounds | Organic and/or inorganic mercury compounds | Metallic mercury and amalgam should be disposed of as solid waste. |

| II. Cyanide compounds | Free cyanide Cyanide complexes | To prevent the generation of toxic cyanide gas, adjust the pH to 10 or higher, even if only cyanide complexes are included. |

| III. Hazardous heavy metal compounds | Compounds with hazardous heavy metal; Cr, Pb, Se, Cd, As. Including Cr(III). | Liquid waste containing hazardous metals, even in trace amounts, should be classified as category III. |

| IV. General heavy metal compounds | Compounds with Fe, Ni, Co, Zn, Cu, Mn, Ga, V, Ge, Sn, and so on. | Excluding liquid waste containing light metals, such as Al, Mg, Ca and so on. |

| V. Inorganic acids | Hydrochloric acid, nitric acid, sulfuric acid, etc. | Liquid waste containing light metals should be classified as V or VI depending on its pH. Neutral (pH=7) liquid wastes containing inorganic salts should be classified as Category V. |

| VI. Inorganic alkalis | Sodium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, etc. |

【Attention】Liquid waste shown in the table below should be collected during organic liquid waste treatment.

| Type of liquid waste |

|---|

| 1) Photographic waste fluid; fusing solution, developing solution, stopping solution |

| 2) Liquid waste containing complexing agents, such as EDTA, tartaric acid |

| 3) Liquid waste containing organic phosphorous compounds |

Substances should not be mixed with inorganic liquid waste

| Solids | Solids in the liquid waste are removed using a 100 mesh wire mesh, as they interfere with the process. Consult with the center's staff when disposing of solid waste that has been separated from liquid waste. |

| Organic Compounds | As a rule, liquid waste mixed with organic matter should be discharged as organic liquid waste. For very small quantities, consult the center's staff. |

| Hazardous Substances | Substances that pose a risk of causing significant health problems to workers during treating. Compounds containing Be, Tl, or Os, nickel carbonyl, acidic wastewater containing cyanide compounds |

| Substances with Explosion Hazards | Substances that pose an explosion hazard when mixed with cyanide treatment agent, sodium hypochlorite. Substances with explosion hazards, such as peroxides, perchlorates, and so on. |

Waste liquid application system

▼

Inorganic liquid waste treatment will be carried out twice a year, around June and December.

Those who need to treat inorganic liquid waste should submit a web application through the Waste Liquid Application System.

Waste Liquid Application System

- The application period for the treatment will be announced by e-mail. Those who require inorganic liquid waste treatment are encouraged to apply through the Waste Liquid Application System; https://kit-wlas.net/app/, within the application period.

- Log in to the system with your lab account. If you do not have an account, please contact Center for Environmental Science.

- Liquid waste should be registered to the application system for each container.

- The input fields are as shown in the table below.

| Input fields | Items to be entered | Notes |

|---|---|---|

| category | Choose one of the twelve categories described below | |

| volume | Only designated 20L polyethylene tanks can be carried in. | |

| Names and each concentrations | names and each concentrations of substances contained in liquid waste | Describe the substances contained in the liquid waste as detailed and accurate as possible. Incomplete forms may not be accepted for processing. |

| pH | Make sure it matches the category of the liquid waste. | |

| Chemical formulas of cyanide compounds | If cyanide compounds are included, enter their chemical formulas. | Cyanide compounds contained should be labeled on the tanks. |

| Element symbols of hazardous heavy metals contained | Enter the element symbols for the following metals, if any. Cr, Pb, Se, Cd, As | Hazardous heavy metals contained should be labeled on the tanks. |

| Information about the payment source | Administrator, funding source, and purpose | The beneficiary's share of the disposal cost will be collected in the following fiscal year along with that of organic liquid waste. |

| Information on the person responsible for the discharge | Names of the affiliation, laboratory and the person in charge. Contact information; extension number and e-mail address | If it was generated by a student experiment, please enter the name of the experiment as well. |

Liquid waste is stored in six categories according to its contents as described earlier, but when discharging, the pH should be measured in each tank and divided into 12 categories as shown in the table below.

When you input the information into the system, choose one of these 12 categories.

| Disposal category | ||

|---|---|---|

| I Liquid waste containing mercury | ||

| II Liquid waste containing cyanide | ||

| III Liquid waste containing hazardous heavy metals; Cr, Pb, Se, Cd, As | ||

| III-1. Acidic | III-2. Alkaline | |

| IV Liquid waste containing general heavy metals | ||

| IV-1. Strongly acidic | IV-2. Strongly alkaline | |

| IV-3. Acidic | IV-4. Alkaline | |

| V Inorganic Acid | ||

| V-1. Strongly acidic | V-2. Acidic | |

| VI Inorganic Alkali | ||

| VI-1. Strongly alkaline | VI-2. Alkaline | |

Carrying in the waste liquid tanks

▼

Containers of liquid waste to be disposed of should be brought to the liquid waste treatment site on the designated date.

Procedures for carrying in

- Those who have applied for inorganic liquid waste treatment are required to bring the containers of liquid waste to the liquid waste treatment site on the designated date notified by e-mail.

- Affix three labels to each container: 1) a label printed with the reference number, laboratory name and contents, 2) a label indicating the category of the liquid waste, and 3) a label indicating the pH level.

- In addition, the labels must be affixed with the name of the cyanide compound if it contains cyanide, or the name of the hazardous metal if it contains a hazardous heavy metal.

- After labeling, put the containers in place.

Treatment of inorganic liquid waste

▼

Inorganic liquid waste collected by licensed contractors is transported to a treatment plant for disposal.

Treatment of inorganic liquid waste

Inorganic liquid waste, excluding mercury-containing liquid waste, is transported and disposed of by Asahi Pretec Corporation.

Most of the liquid waste goes through intermediate processes of coagulation sedimentation, cyanide decomposition, and neutralization at the Kobe Plant before being transported to a final disposal site for incineration.

A part of the residue after incineration is recycled as cement material, etc., while the rest is landfilled at a controlled final disposal site.

Liquid waste containing mercury compounds is transported by Kyokko-Sangyo Co., Ltd. to Itomuka Plant of Nomura Kohsan Co., Ltd. together with solid waste containing/contaminated with mercury.

Mercury vaporized by the calcinating furnace is recovered and used as a reagent or reused in fluorescent lamps and special measuring instruments.

Returning the waste liquid tanks

After the waste liquid treatment is completed, users will be notified by e-mail of the date and time to return the containers.

Please be punctual and come to the center to collect them.